Lightweight Semiconductor Packaging Post-Flattening Die Fixture

Current Bottlenecks:

- Existing in-house fixtures are prone to damage and deformation, and their use is cumbersome, leading to increased personnel burden.

- The existing in-house fixtures are of old-fashioned design, with excessive volume/weight, limiting the quantity of oven equipment according to specifications and affecting product throughput.

- The old fixtures have a prolonged cooling time after exiting the oven, resulting in extended cycle times in the PMC process.

- Poor capability to improve product warpage.

Objectives:

- Design dedicated oven fixtures based on characteristics (considering product throughput/weight/volume/operator convenience, etc.).

- Increase throughput in terms of quantity and cooling efficiency to increase PMC process capacity UPH. Effectively reduce cycle time and improve fixture turnover rate.

- Higher durability compared to old fixtures.

- Effectively address product warpage issues.

Application Benefits:

81% lighter than traditional fixtures, significantly increasing baking volume and reducing cooling time and overall cycle time.

- Oven loading capacity increased by 25% UPH.

- Oven process efficiency can be increased by 39% UPH. *This data is based on actual measurements in the packaging plant.

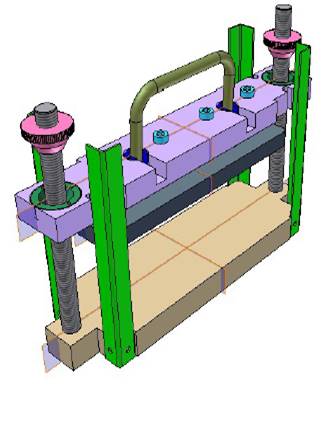

Appearance Description:

Oven fixture compression fixture

Oven baking fixture